Raising the Standard: Why Architects Should Specify UL’s TEDP-Accredited Firestop Manufacturers

When designing for life safety, you rely on more than just product specs—you rely on trusted systems, tested solutions, and credible documentation. In firestopping, where conditions on-site often don’t match what’s in a tested listing, engineering judgments (EJs) become an essential tool. But without a standard process, the quality of those EJs can vary widely.

That’s why UL Solutions introduced the Technical Evaluation Developer Program (TEDP)—a voluntary accreditation program that sets a new industry benchmark for how technical evaluations (which are more commonly referred to as EJs) are developed, documented, and supported.

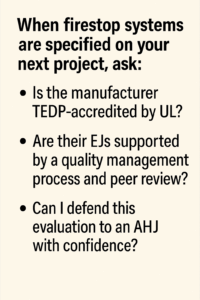

If you’re an architect or registered design professional, here’s why specifying TEDP-participating firestop manufacturers is a smart move for your projects:

Confidence in Technical Documentation

TEDP requires manufacturers to demonstrate technical expertise, document their evaluation processes, and adhere to a UL-audited quality management system. They must also submit to regular audits, pass technical exams, and agree to random testing of selected EJs. As a design professional, this means you can trust the accuracy, consistency, and rationale behind the technical evaluations you rely on.

Improved Code Compliance and Risk Mitigation

TEDP is designed to support better compliance with IBC, NFPA, and NBCC fire resistance requirements. Participating manufacturers are held to a higher standard, helping you mitigate liability and reduce the risk of rejected designs or field modifications. Incorporating TEDP-approved manufacturers into your specs adds an extra layer of protection by ensuring your firestop strategy is backed by robust engineering and oversight.

Support for Complex or Uncommon Conditions

Architectural innovation often means encountering firestop conditions that aren’t covered by tested systems. TEDP helps bridge this gap by raising the quality of EJs—ensuring they are based on valid testing data, sound engineering principles, and properly documented justifications. TEDP makes it easier to defend design decisions and submit credible alternatives when site conditions diverge from standard listings.

Greater Transparency for AHJs and Specifiers

All TEDP-accredited companies are listed in UL’s Product iQ database under a dedicated category (WYGB), making it easy for code officials, engineers, and design professionals to verify program participation. This visibility enhances credibility and ease of approval, especially during plan review or inspection stages.

Driving Industry Advancement

TEDP isn’t just about quality control—it’s about raising expectations. This promotes the conversion of commonly used EJs into listed systems, improving future design and construction options for all stakeholders.

By incorporating TEDP-accredited firestop manufacturers into your specifications, you’re not only ensuring technical rigor and code alignment—you’re demonstrating leadership in life safety design. TEDP supports better documentation, increased transparency, and improved long-term outcomes for both new construction and renovation projects. In a field where safety is non-negotiable, choosing TEDP means choosing accountability, quality, and trust.

To view accredited manufacturers, search UL’s Product iQ under the Technical Evaluation Developer Program (TEDP) category: https://productiq.ulprospector.com.

Learn more at our TEDP FAQ page, Resources and FAQs for the UL Technical Evaluation Developer Program.