Perimeter Fire Containment

What is Perimeter Fire Containment (PFC)?

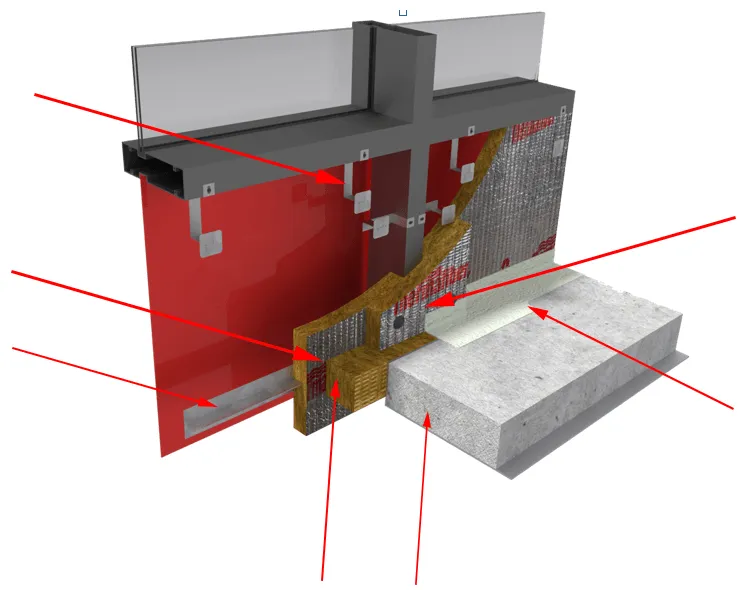

Architects and curtain wall designers have long recognized that the void created between the floor slab and exterior wall if left unprotected, would allow fire and smoke to propagate to the floor above. The logical fix seemed to be to fill the void with fire-resistant material. However, if the void is simply filled with mineral wool and a portion of the spandrel area is left unprotected, the curtain wall will fall, causing the mineral wool to fall out of the void. Once the mineral wool at the void is lost, fire will propagate through the opening, allowing fire to engage combustibles in the floor above.

Architects and curtain wall designers have long recognized that the void created between the floor slab and exterior wall, if left unprotected, would allow fire and smoke to propagate to the floor above. The logical fix seemed to be to fill the void with fire resistant material. However, if the void is simply filled with mineral wool and a portion of the spandrel area is left unprotected, the curtain wall will fall, causing the mineral wool to fall out of the void. Once the mineral wool at the void is lost, fire will propagate through the opening, allowing fire to engage combustibles in the floor above.

Perimeter Fire Containment is designed to prevent flame and hot gasses from entering the room above via the void created at the intersection of the floor slab and the interior of the exterior wall assembly. WHY is this necessary? THE ANSWER: The unprotected void at the edge of slab becomes a chimney or flue for fire to rage up the inside of the building, transmitting fire from floor to floor in the building. Often overlooked is how much exposure is actually created by the void at the edge of the building. A small building with a perimeter of 200′ x 200′ and a typical void of 3″ creates 200 square feet of open area that will allow smoke and hot gasses to flow freely to the floor above. Multiply this open area times the number of floors and the risk to life safety of the occupants and first responders becomes a magnitude unthinkable to a building owner or community.

Mechanical Attachment- is defined as the positive connection of fastening devices by welding or screw- attachment of curtain wall insulation. Mechanical attachment is typically required for aluminum-framed curtain walls.

Reference UL/Intertek system for type of fastener as well as spacing of fasteners.

Types of fasteners cannot be mixed and matched from tested listed system to system. Fastener installation is specific to tested/listed system.

Caution- adhesive or glue applied fasteners will not adequately perform at under fire conditions.

Check with mineral wool manufacturers to determine the correct insulation product that has been tested to ASTM E 2307.

Mineral wool spandrel insulation needs to be slightly oversized to fit within spandrel opening. There should be no gaps or spaces between framing and edges of curtain wall insulation. These gaps would allow for flame and hot gases to pass through any openings.

Typically vertical seams are not allowed without proper reinforcement member to support the seams.

Horizontal seams allowed, however, reference tested listed system for location and number of seams allowed.

Spandrel insulation typically foil faced on one side. Foil facing (FSK or FSP) provides a vapor barrier. Seams at spandrel insulation edges to be taped with aluminum foil tape to provide continuous vapor barrier. Reference tested/listed assemblies.

Spandrel Insulation installed flush with interior face of the framing.

Min. 1” air space required between spandrel insulation and glass.

Spandrel Insulation to be mineral wool, check UL or Intertek Listing for approved manufacturer.

UL systems will list spandrel insulation by product name, manufacturer and required thickness and nominal density.

Exterior wall Insulation to be mineral wool, check UL or Intertek Listing for approved manufacturer.

UL systems will list Exterior wall insulation by product name, manufacturer and required thickness and nominal density.

Exterior wall Insulation typically friction fit to completely fill all stud cavities of curtain wall above and below top of slab. See specific system for details. Some

UL/Intertek assemblies allow for glass fiber insulation in the stud cavity for some steel-framed exterior walls.

(note: all ASTM E2307-listed assemblies for aluminum-framed curtain walls require mineral wool insulation)

Some form of backer/reinforcement is required in perimeter fire containment systems for appropriate backer/reinforcement..

This is required to keep the Spandrel insulation from bowing due to the compression of the safing insulation within the void between the floor slab and exterior wall.

If proper compression is not maintained, then voids created at the curtain wall/safing intersection will allow fire and hot gases to pass through the joint.

Refer to the UL/Intertek tested and listed system for appropriate backer/reinforcement.

Typical backer/reinforcement members include T- Bars, L-angle or hat channels constructed 20 gauge galvanized steel. Refer to tested/listed system for specific gauge.

Aluminum backer reinforcement is unacceptable as it will melt out when exposed to fire as it will melt out when exposed to fire..

Forming material is typically a nominal 4 pcf mineral wool insulation, compression-fit within the linear void between the face of the edge floor slab and exterior curtain wall insulation.

Forming material is installed to prevent the interior passage of flame and hot gases at the perimeter joint.

Refer to the UL/Intertek tested and listed system for proper orientation, depth, and compression.

Compression calculations from UL:

Tuncomp=(WnomX100)/(100-Icomp)

Where:

Tuncomp = Uncompressed Thickness Necessary, in.

Icomp = Insulation Compression Percentage Specified in System, percent

Wnom = Nominal (Installed) Joint Width, in.

Intertek

Required width of insulation to be installed in joint:

(Wnom x 100)/(Icomp-100) = I cut

Wnom = Nominal Joint Width or installed joint width

Icut= Insulation Cut Width or (compress/install in Wnom)

Icomp = Insulation Compression (%)

Verifying Compression:

((Icut- Wnom)/Icut) x 100 = I comp

Wnom= Nominal Joint Width (installed joint width)

Icut= Insulation cut Width (compress and install in Wnom)

Icomp = Insulation Compression (%)

Fill, Void Material is typically spray applied, however other acceptable smoke barrier materials can be in the form of tapes, poured in place or troweled over the forming material to impede the passage of smoke at the perimeter void.

Fill, Void Material is also installed to accommodate movement of the joint.

Fill, Void Material are generally elastomeric coating, having fire resistive properties.

Refer to the UL/Intertek tested and listed system for proper thickness and installation technique.

Mullion covers are typically required in aluminum-framed perimeter fire containment systems.

Aluminum framing melts at a relative low temperature and needs to be protected.

Additionally mechanical fasteners attached to aluminum frame work needs to be protected in order to keep the curtain wall insulation securely in place.

System integrity is predicated on the aluminum framed spandrel maintaining its integrity during a fire event.

Mullion Covers are made out of mineral wool curtain wall insulation.

Refer to the UL/Intertek tested and listed system for required characteristics, location, and attachment method.

Mullion Cover Mineral Wool Insulation must be UL/Intertek approved per ASTM E 2307

To maintain continuous vapor barrier, mullion covers can be foil faced and taped.

Mullion covers also provide thermal protection to vertical framing members.

Not currently addressed by ASTM E 2307 testing however, has been identified as a potential failure point in the system if left unprotected.

Reference UL XHDG Design Guide for recommended methods of protection.